Construction projects today are more complex than ever. From towering skyscrapers to intricate infrastructure, the demand for precision, efficiency, and collaboration has pushed the industry to adopt new technologies. At the heart of this evolution are Building Information Modeling (BIM) and 3D modeling, which have transformed how projects are planned and executed. A critical component within this digital framework is the rebar shop drawing, which ensures the structural integrity of concrete structures.

This post will explore the vital role of rebar shop drawing services in BIM and 3D modeling. We will cover what these drawings are, their benefits when integrated into a BIM workflow, and the best practices for making this integration successful. Understanding this connection is key for any construction professional looking to stay competitive and deliver high-quality projects on time and within budget.

What Are Rebar Shop Drawings?

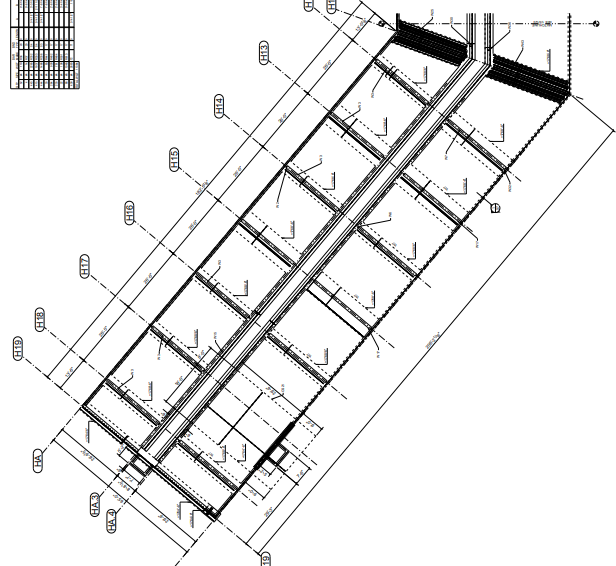

Rebar shop drawings are detailed blueprints used by rebar fabricators to cut, bend, and assemble reinforcing steel for concrete structures. Think of them as the precise instructions that translate an engineer’s structural design into a tangible, ready-to-install product.

These drawings go beyond the general reinforcement plans provided by structural engineers. They specify every detail, including:

- The exact size, shape, and length of each bar.

- Bend details and angles.

- Placement locations within the concrete formwork.

- Quantities and bar marks for easy identification.

- Bar lists or schedules that summarize all the reinforcement needed.

Essentially, rebar shop drawings are the bridge between design and fabrication. They ensure that the rebar delivered to a construction site is accurate and fits perfectly, preventing costly delays and rework.

An Overview of BIM and 3D Modeling

Building Information Modeling (BIM) is an intelligent, 3D model-based process that gives architecture, engineering, and construction (AEC) professionals the insight and tools to more efficiently plan, design, construct, and manage buildings and infrastructure.

Unlike traditional 2D drawings, a BIM model is a digital representation of the physical and functional characteristics of a facility. It’s a shared knowledge resource, allowing all stakeholders—architects, engineers, contractors, and fabricators—to collaborate within a single, unified environment.

3D modeling is the foundation of BIM, creating a visual and data-rich model of the project. This allows teams to visualize the entire structure, identify potential issues, and make informed decisions long before construction begins.

Key Benefits of Rebar Shop Drawings in BIM

Integrating rebar shop drawings into a BIM framework offers significant advantages over traditional methods. When reinforcement details are modeled in 3D, the entire project benefits from enhanced accuracy, communication, and efficiency.

Enhanced Accuracy and Clash Detection

One of the most powerful features of BIM is its ability to detect clashes. By creating a detailed 3D model of the rebar, teams can see exactly how it will interact with other building components, such as plumbing, electrical conduits, and mechanical systems. This clash detection process identifies conflicts that would be nearly impossible to spot in 2D drawings, allowing for adjustments before fabrication even begins. This proactive approach minimizes on-site modifications, which are often time-consuming and expensive.

Improved Communication and Collaboration

BIM creates a single source of truth for the entire project team. When rebar shop drawings are integrated into the central model, architects, engineers, and fabricators can all access the same up-to-date information. This eliminates confusion caused by outdated drawing sets and improves coordination. If a design change occurs, the model is updated, and all stakeholders are immediately aware of the implications for the rebar layout. This collaborative environment fosters better decision-making and a more cohesive workflow.

Streamlined Fabrication and Installation

3D rebar models provide fabricators with crystal-clear instructions. They can visualize the final assembly, understand complex geometries, and produce more accurate bar bending schedules. Many fabrication shops can now directly use the data from the BIM model to automate their cutting and bending machines, reducing the chance of human error. On-site, installation crews have a clear visual guide for rebar placement, which accelerates the installation process and ensures it aligns with the design intent.

Cost Savings and Reduced Material Waste

By improving accuracy and minimizing on-site errors, the integration of rebar shop drawings in BIM leads to significant cost savings. Clash detection prevents expensive rework, and streamlined fabrication reduces labor costs. Furthermore, precise bar bending schedules generated from the model help optimize material usage, leading to less waste. Accurate quantity take-offs from the model also ensure that the right amount of material is ordered, preventing budget overruns.

Best Practices for Integration

To fully leverage the benefits of rebar shop drawings in BIM, organizations should follow a set of best practices.

- Software Compatibility and Interoperability: Ensure that the software used for rebar detailing (like Tekla Structures or AutoCAD) is compatible with the primary BIM platform (such as Autodesk Revit). Smooth data exchange is crucial for a seamless workflow.

- Establish Clear Standards: Develop and adhere to company or project-specific standards for modeling, naming conventions, and data sharing. This consistency ensures that everyone on the team can easily understand and use the model.

- Invest in Training and Expertise: The transition to a BIM-centric workflow requires skilled professionals. Investing in training for your team or partnering with experienced providers of rebar shop drawing services, like Chudasama Outsourcing, can ensure high-quality results. An expert partner can bring deep knowledge of industry standards and software capabilities.

Common Challenges and How to Overcome Them

Despite the clear benefits, integrating rebar detailing into BIM can present some challenges.

- Model Complexity: Detailed rebar models can become very large and complex, potentially slowing down software performance. Use best practices for model management, such as breaking the project into smaller, manageable zones and optimizing hardware.

- Resistance to Change: Some team members may be hesitant to move away from traditional 2D workflows.Demonstrate the value of BIM through pilot projects and provide comprehensive training. Highlight how the new process makes their jobs easier and more efficient.

- Lack of Skilled Detailers: Finding detailers with expertise in 3D rebar modeling can be difficult. This is where outsourcing to a specialized firm like Chudasama Outsourcing can be invaluable. Accessing a pool of experienced professionals ensures your project is in capable hands without the overhead of hiring and training an in-house team.

The Future is Digital and Integrated

The integration of rebar shop drawings into BIM and 3D modeling is no longer a futuristic concept—it is a present-day necessity for efficient and successful construction. The ability to visualize, analyze, and coordinate reinforcement in a digital environment provides unparalleled advantages in accuracy, collaboration, and cost-effectiveness.

As technology continues to advance, we can expect even tighter integration, with AI-powered tools optimizing rebar designs and robotics automating on-site installation. For construction firms looking to thrive, embracing this digital transformation is not just an option; it’s the key to building the future.

If your organization is ready to enhance its construction processes, exploring professional rebar shop drawing services is a logical next step.